|

If you are interested in the actual process of making custom leather accessories, here are a few pictures that will help you understand what goes in to making each custom leather accessory... The first step is to cut the leather to fit the accessory...I use the actual accessory (or a custom made form) to fit the case perfectly to the accessory.

If the accessory could be damaged by exposure to moisture, it is securely wrapped in plastic to protect it during the process...this is necessary since most of my cases are "wet formed" so they fit the accessory like a glove.

During the wet forming, the accessory (or form) is clamped in the case so the leather conforms to the exact outside dimensions.

If the case is to be lined with deerskin or suede, it is stretched and the back and liner are coated with a heavy duty contact cement.

After the lining is glued in, the front and back parts are prepared for attachment using the same contact cement.

Then its time to begin forming the belt loop (if the design calls for one). Most of my case backs are made from very heavy duty 8 oz. leather so they will last many years. The loop is glued AND stitched from one continuous piece of leather.

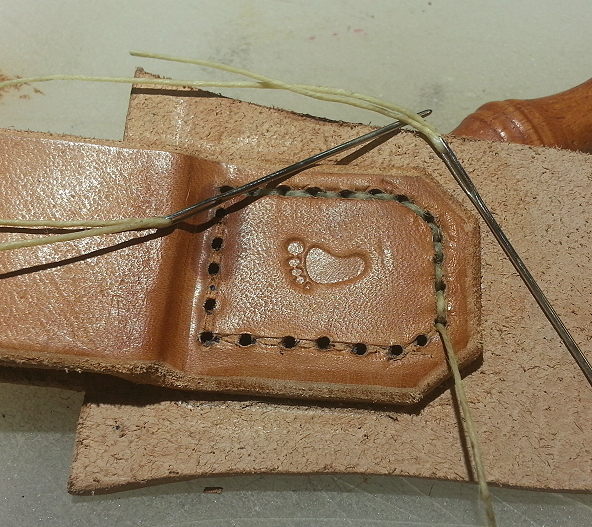

I use only heavy duty wax coated nylon thread for all my projects. I also use the "saddle stitch" which requires two needles to be used at the same time. This stitch allows me to pull each individual stitch tight to be sure the case is as secure and durable as possible.

Once the belt loop has been finished, its time to glue the front of the case to the back....it is clamped and allowed to dry overnight.

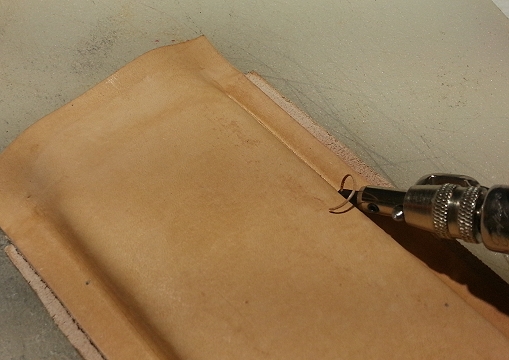

A stitching grove is then cut to not only give me a straight line of stitches, but to lower the thread so there is less wear and tear on it.

If the device has irregular surfaces (i.e. pistol) I will clamp the wet leather to get it to conform to all the highs and lows of the device so it will result in a custom fit

.Stitching holes are measured and marked, then punched before the leather is dyed. This is to enable the dye to penetrate the holes to provide an even cover over the entire case.

Once the case has been dyed and finished with a clear protective coating, it is hand stitched. I even wear leather stitching gloves so each individual stitch can be tightened as much as possible.

After the stitching is completed, the edges are treated with a special compound and burnished to provide a long lasting, smooth edge.

Call me at 214-773-7377 or Email Me to place your order today! - Back -

|